-

05-25 2025

Can Casting Sand Be Reused?

When many people hear sand casting, their first reaction may be: Wow, how much sand does this take?

-

05-23 2025

What Sand Is Used For Sand Casting?

Many people who don't know much about the foundry industry should have been curious about what kind of "sand" sand casting uses?

-

05-22 2025

How Accurate Is Sand Casting?

When many people learn about casting technology, they often ask: "Is sand casting precision high?" This question is very practical.

-

05-13 2025

What Is The Advantage Of Sand Casting?

In fact, the biggest advantage of sand casting is flexibility, low cost and wide adaptability.

-

05-03 2025

What Is The Minimum Wall Thickness For Sand Casting?

When it comes to sand casting, many people will be curious: What is the minimum wall thickness of sand casting? Generally speaking, the minimum wall thickness of sand casting is about 5 mm. If the wall is too thin, the liquid metal is prone to insufficient filling, pores, cracks and other problems during pouring and cooling, so 5 mm is a more reasonable and safe design reference.

-

05-01 2025

Is Sand Casting Strong?

When many people hear sand casting for the first time, they will think that it is not strong enough because of the word "sand". In fact, on the contrary, the sand mold is only a mold material used to form the shape of the casting, and the final shape is high-temperature molten metal, such as cast iron, carbon steel, stainless steel, etc.

-

04-30 2025

What Is Sand Casting GCSE?

In the GCSE course, sand casting is a very classic metal manufacturing process. Simply put, sand casting is to first make a casting mold with sand, pour the molten metal into it, wait for it to cool and solidify, knock off the sand, and a complete metal part is born.

-

04-28 2025

How Long Does Sand Casting Take?

How long does sand casting take? This is a question that many customers will be curious about at the beginning. In fact, the cycle of sand casting is affected by many factors, such as the size of the casting, the complexity of the shape, the mold preparation time, and the subsequent cleaning and processing procedures.

-

04-17 2025

Why Is Sand Casting Still Used Today?

When it comes to metal casting, many people will immediately think of those high-end automated production lines and sophisticated processing equipment. But do you know? To this day, sand casting still occupies an irreplaceable position in various manufacturing industries.

-

04-16 2025

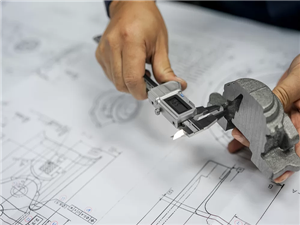

How To Make Gearbox Housing Wear Resistant?

Among various mechanical equipment, the engine and gearbox can be said to be a combination of "heart + center". And their shells - that is, the part that bears strong power and resists high temperature and high pressure - are often produced in the sand casting way. Why choose sand casting? Because it is stable, strong and precise enough!