-

06-09 2025

How Many Times Can Casting Sand Be Used?

If you are also interested in sand casting technology welcome to learn about our production line.

-

06-07 2025

Why Sand Casting Cost Low?

Compared with other casting methods, such as precision casting, metal mold casting or die casting, sand casting is indeed a relatively cheap casting method that is suitable for a variety of product shapes and production requirements.

-

05-30 2025

Do You Know the Difference Between Various Types of Sand Molds in Sand Casting?

Sand casting is mainly divided into three types: water glass sand, resin sand, and coated sand. The main difference between them is that they use different binders and curing agents, so their production processes are different.

-

05-29 2025

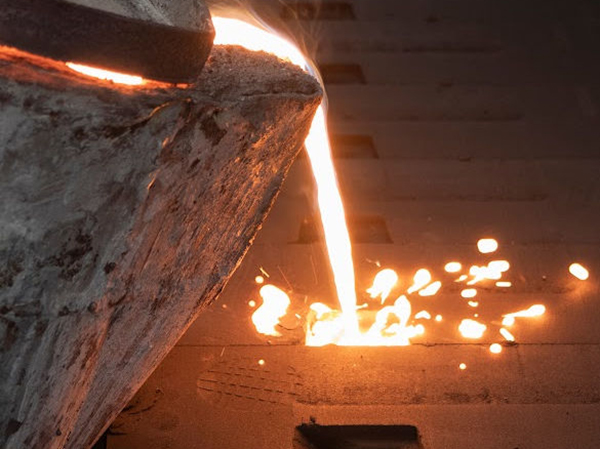

How to make a good casting from a piece of iron?

During "Sand casting", first place the lower mold on a flat plate, put a sand box, fill the sand and scrape it tightly. After the lower mold is made, turn the sand mold 180 degrees, put the upper mold, sprinkle the parting agent, put the sand box, fill the sand and make it tight and flat, turn the upper sand box 180 degrees, take out the upper and lower molds respectively, then turn the upper mold 180 degrees and put it together with the lower mold. The sand mold is made and waiting for pouring. This process is commonly known as "sand casting".

-

05-27 2025

What Is Better Than Sand Casting?

Customers often ask us: "Aren't there more advanced casting technologies now? For example, precision casting, die casting, and 3D printing casting, are they better than traditional sand casting?"

-

05-25 2025

Can Casting Sand Be Reused?

When many people hear sand casting, their first reaction may be: Wow, how much sand does this take?