What Is Sand Casting GCSE?

In the GCSE course, sand casting is a very classic metal manufacturing process. Simply put, sand casting is to first make a casting mold with sand, pour the molten metal into it, wait for it to cool and solidify, knock off the sand, and a complete metal part is born. This method has a long history and is flexible to operate. It is a very important basic process in industrial manufacturing.

In a course setting like GCSE, students mainly need to understand the basic process, advantages and disadvantages of sand casting and its practical application. For example, in the production process of sand casting, a prototype model is required to press the sand to form a mold, and a special pouring channel and exhaust hole are required. Wait until the metal solidifies and forms, disassemble the sand mold, and then carry out necessary cleaning and polishing, and a complete part can be used. Because sand is cheap and easy to form, this method is particularly suitable for making metal parts with complex shapes or small quantities.

Doesn't it sound interesting? In fact, in real industrial production, the role of sand casting is far more important than what is said in textbooks. In our fuding factory, the production of sand casting is no longer as simple as traditional manual operation. We have advanced automatic molding equipment, which can efficiently produce castings of various materials and sizes. Whether it is a small spare part or a heavyweight large machine base, we can easily handle it.

Our sand casting product range is very wide, covering gray iron castings, ductile iron castings, carbon steel castings, stainless steel castings, etc., which are widely used in mechanical equipment, automotive parts, construction machinery, pump and valve accessories and other fields. Whether the customer needs a single piece of customization or mass production, we have a complete solution. From casting to subsequent heat treatment, machining, and surface treatment, each process is responsible for a professional team to ensure that every product is of good quality.

When it comes to production capacity, we are really proud. Our factory covers a large area, has multiple efficient sand casting production lines, equipped with advanced melting furnaces, automatic molding machines, shot blasting machines and other equipment, with an annual production capacity of thousands of tons. Whether it is an urgent order, a difficult order, or a high-demand project that requires complex processes, we can respond quickly and deliver stably.

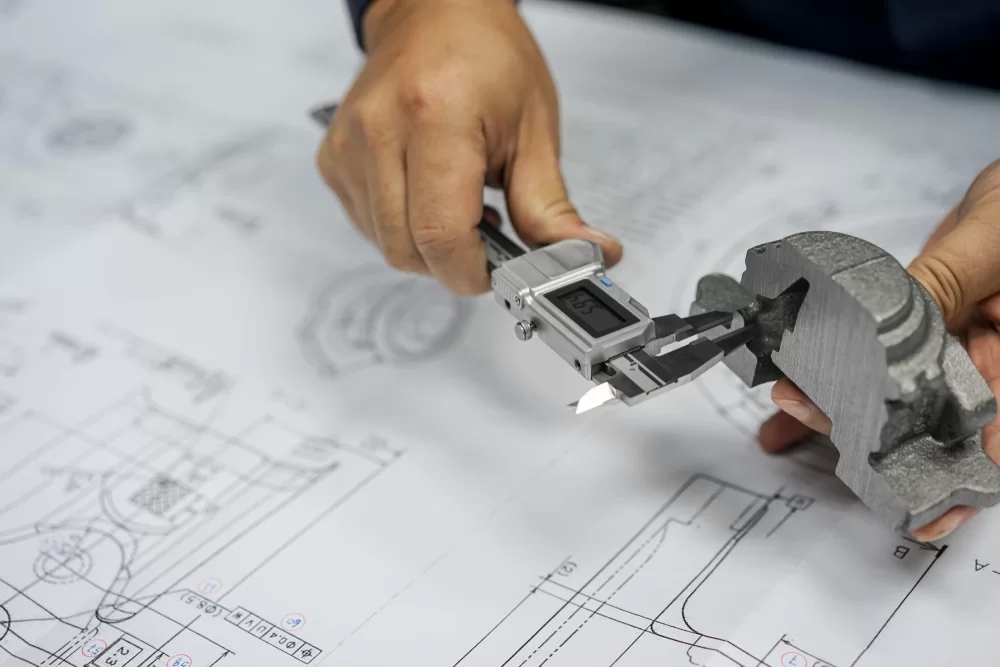

Moreover, we attach great importance to product testing and quality control. Each batch of sand casting will go through strict inspection processes such as dimensional measurement, metallographic analysis, and non-destructive testing to ensure that the products not only meet the customer's design standards, but also perform well in practical applications. Because of this, we have won the trust and cooperation of more and more customers at home and abroad.

If you are also interested in sand casting or are looking for a reliable sand casting manufacturer, you are very welcome to contact us. Whether it is a new product development for a small trial or a stable supply of large quantities, we can give you a satisfactory answer. Want to know more details? Come and chat at any time, we are waiting for you here!