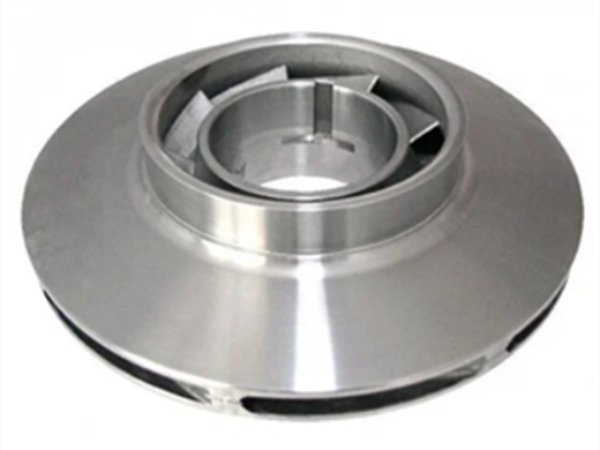

Semi Open Impeller for Centrifugal Pump

1. The new Semi-open vane impeller is made of cast iron, which is resistant to wear and corrosion.

2. With a semi-open structure to simplify the internal layout, the Semi-open vane impeller is small in size and easy to install, and is suitable for many pump bodies.

3. The new Semi-open vane impeller has a simple structure, easy to disassemble and clean, and reduces downtime.

Half-open centrifugal pump impeller introduction:

Half-open centrifugal pump impeller is a rotating part of a centrifugal pump design that transmits energy from the pump motor to the fluid. The half-open centrifugal pump impeller consists of blades that come out of the inlet that is open in the center and generate centrifugal force when rotating. Due to the centrifugal force, the fluid moves from the shell to the outlet point. Our Half-open centrifugal pump impeller is carefully built using sand casting technology. Sand casting can design the complex structure of the impeller to meet different needs. Our semi-open vane impeller materials have also been strictly screened and processed, have high strength and corrosion resistance, semi-open impeller are suitable for working conditions with impurities and high wear, and provide power support for water supply and drainage, industrial processes, etc.

Semi-open vane impeller application:

Urban sewage treatment: In urban sewage treatment plants, centrifugal pump impeller delivers impurity sludge water, and rainwater pumping stations drain water to deal with large flows and debris during the rainy season.

Suitable for mining: Centrifugal pump impeller handles high-wear substances such as ore slurry and tailings.

Suitable for industrial production: In the chemical and metallurgical industries, Semi-open impeller transports liquids containing particles, fibers and other media, such as chemical pastes and metallurgical wastewater treatment.

Suitable for agricultural irrigation: Centrifugal pump impeller can transport sediment-containing irrigation water, which is suitable for harsh water quality environments to ensure the stability of the irrigation system.

Imported food: We can customize semi-open impellers made of stainless steel, which meet hygiene standards.

Advantages of sand casting:

1. Cost-effectiveness: The investment in equipment and molds is relatively low. When producing semi-open impeller in small batches and multi-varieties, the cost can be effectively controlled and the cost performance is high.

2. High flexibility: Semi-open impellers can be used with many complex impeller structures, presenting a unique flow channel and shape of semi-open impellers to meet customized needs.

3. Wide material adaptability: strong compatibility with casting materials, cast iron, cast steel, etc. are selected according to Semi-open impeller working conditions to ensure a balance between performance and economy.

Why choose us semi-open impeller?

Our semi-open impellercan achieve higher traffic with the same energy consumption, helping users reduce long-term operating costs.

At the same time, we have a professional technical team, which can carry out personalized design and customized production according to the specific needs of customers, including flow, head, media characteristics, installation space, etc.

From the drawing of design drawings to the trial production and testing of samples, to the final mass production of semi open impeller for centrifugal pump, we will strictly control every link to ensure that the customized semi open impeller for centrifugal pump meets the customer's expectations and actual use needs.

Our service:

1. Regular reporting: After the order is confirmed, feedback the production progress of the product to the customer in a timely manner. Through regular communication and reports, let customers know the production status of semi open impeller for centrifugal pump.

2. Logistics guarantee: After the production of Semi-open vane impeller is completed and the inspection is qualified, we will use professional packaging materials and methods to properly pack the impellers to prevent damage during transportation.

3. Quick response: When customers encounter half-open semi-open vane impeller failures or technical problems, we provide a 24-hour after-sales service hotline to ensure that customers can contact our after-sales team in time. After receiving customer feedback, the after-sales staff will respond quickly to solve the problem in the shortest possible time and reduce customer losses.

About us:

Dandong Fuding Engineering Machinery Co., Ltd., has been doing research and development of pump components for many years, accumulated rich technical experience, and produced high-quality Centrifugal pump impeller. From the purchase of raw materials to the delivery of finished products, we will carry out strict quality inspection to ensure the quality of our half-open centrifugal pump impeller. And we have also established continuous supply and demand relationships with customers from Germany, Japan, the United States, the United Kingdom, South Korea, Norway, Brazil and other countries. Major companies are welcome to come to consult!