Heavy duty cast iron castor wheel

1. Suitable for Grey Cast iron, GG20/GG25, EN-GJL-200/EN-GJL-250; ductilelron GGG40, GGG50, EN-GJS-400, EN-GJS-450, EN-GJS-500 casting to ensure the Industrial cast iron casters carrying capacity and durability.

2. The new heavy-duty steel wheels is cast in sand mold, with precise dimensions and smooth surface, reducing subsequent processing costs.

3. We provide OEM&ODM services, and the material, size, heat treatment and surface treatment technology of heavy-duty steel wheels can be adjusted according to customer needs.

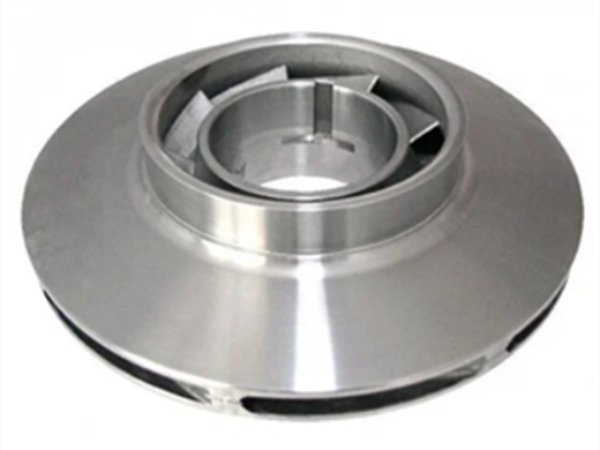

Product introduction:

Heavy-duty steel wheels use cast iron as the base raw material and sand casting process to meet the requirements of different strength and performance. After casting, through deburring and cleaning, a variety of heat treatment, surface treatment and CNC precision machining and other processes, the size, performance and appearance of the industrial steel casters are specified to provide stable and reliable heavy-duty cast iron cast steel casters for industrial equipment movement, which can be used for the installation and handling of various heavy-duty equipment.

Product application:

1. Industrial equipment: Industrial cast iron casters are suitable for high-load scenarios such as heavy machinery, machine tools, and automated production lines.

2. Engineering vehicles: Industrial cast iron casters are used for heavy-duty mobile equipment such as forklifts, cranes, and mining equipment.

3. Logistics and transportation: Industrial cast iron casters are suitable for storage shelves, container trucks, AGV trolleys, etc.

4. Special environment: Heavy-duty steel wheels are high temperature resistant and corrosion resistant, and can be used in chemical, metallurgical, shipbuilding and other industries.

Advantages of sand casting:

High-precision sand casting can produce complex structures, reducing the subsequent processing of heavy-duty steel wheels.

The internal structure of aluminum alloy castings is tight and the impact resistance is strong.

The product is suitable for small and medium-sized mass production industrial steel casters, low mold cost and short delivery cycle.

The casting process can be adjusted to meet the needs of different hardness, toughness and wear resistance.

Product comparison:

material | advantages | Disadvantages |

Industrial cast iron casters | Industrial steel casters extreme durability, high load capacity | Heavier than other materials |

Polyurethane | Suitable for indoor use, low noise | Low durability under heavy loads |

rubber | Suitable for indoor use, low noise | Frequent use may wear out faster |

Stainless steel | Corrosion resistance, suitable for hygiene | Usually more expensive |

Product precautions:

1. Heavy-duty steel wheels cannot be overloaded and will cause the wheel body to break and the bracket to break.

2. The lateral force cannot be ignored, which will cause the bearing to get stuck and cause steering failure.

3. If industrial steel casters are maintained irregularly, lubrication will fail and rolling resistance will increase.

Maintenance tips for heavy-duty cast iron cast steel casters:

With proper maintenance, the life of heavy-duty cast iron cast steel casters can be extended.

Please check regularly for signs of wear, damage, or excessive rust. Early detection prevents major problems in the future.

Therefore, it is necessary to ensure that the bearings are lubricated regularly, reduce friction, improve fluidity, and minimize the risk of overheating.

In order to keep the wheels clean from dust, debris, and dirt accumulation, these materials can prevent movement and cause damage.

About us:

Dandong Fuding Engineering Machinery Co., Ltd., focuses on the research and development and production of heavy cast iron parts, and its products are exported to Europe, America, Russia and other international markets. The company's management personnel conduct strict testing to ensure that Industrial steel casters meet international standards. We have a professional team to provide material selection, process optimization and after-sales support to help customers improve the performance of Industrial steel casters. The company welcomes major companies to cooperate!