How Many Times Can Casting Sand Be Used?

How many times can a sand mold be reused? There is actually no absolute answer to this question. It depends on the sand casting type of sand mold used, the binder added, the type of casting metal, and the recycling and reprocessing capacity on site. Generally speaking, under normal production management and good regeneration conditions, clay sand can generally be reused 20 to 30 times, or even more. As long as there is no serious thermal damage or inclusion contamination, we can keep this piece of sand "active" on the production line.

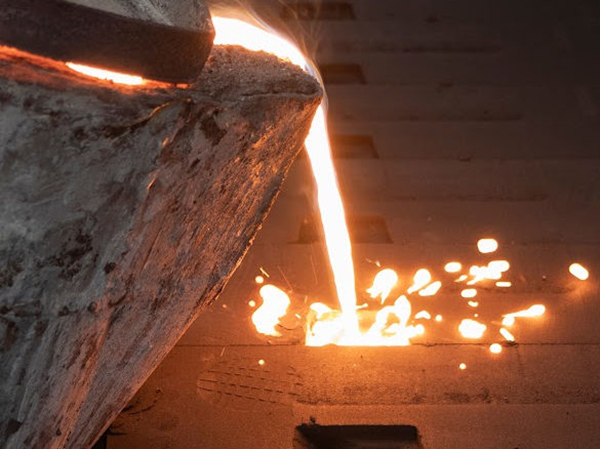

Our factory uses the traditional sand casting process based on clay sand. Although this process has a long history, it still maintains its vitality through continuous optimization and combination with modern equipment. Clay sand is mainly composed of silica sand, bentonite, water and a small amount of additives. It has good plasticity and moderate strength when molding. After each pouring, we will recycle the sand, and use special equipment to demold, crush, screen, dust and cool it, and finally add water and binder to mix it again to make it have the molding ability again.

In our sand casting workshop, you can see a complete closed-loop system - from new sand mixing, molding, pouring, demolding, old sand recycling to recycled finished products, almost zero waste is achieved. This not only reduces production costs, but also greatly reduces environmental pollution. Customers often come to visit and sigh: "Your sand casting process is too environmentally friendly and looks very standardized." Our factory has a strict sand performance testing system, including particle size distribution, mud content, compaction rate, wet compressive strength, air permeability, etc. Only the recycled sand that passes the test can be put back into sand casting. Moreover, our engineers will flexibly adjust the sand mixing ratio according to the requirements of different castings to make each mold sand just right.

In terms of sand casting, we can make castings of various shapes and sizes, whether it is mechanical parts or building components, from tens of grams to hundreds of kilograms of small and medium-sized parts. The entire production line is semi-automated, which improves efficiency while reducing manual errors.

So, how many times can the sand mold be used? This is not just a matter of number, but also reflects the management ability and technical level of a factory. We believe that through professional recycling technology and strict process control, a grain of sand can be used many times in our workshop and always keep in good condition. If you are also interested in sand casting technology, or are looking for a stable and reliable casting supplier, welcome to learn about our production line, we will provide you with the most satisfactory service.